3rd International Workshop Surface quality of continuously cast products – IWSQ-3

Hotel Weitzer Graz

SCOPE

Eight years after the successful first conference on the topic, ASMET, in cooperation with its sister society AIM, organises once again a two-day event focused on the Surface Quality of continuously cast products. The conference venue will be Graz, Austria.

The surface quality of ingots, billets, blooms and slabs is a particularly important issue in order to ensure the required surface quality of final rolled and forged products. This aspect is becoming increasingly significant, especially nowadays, when steelmakers are refocusing their activity on the search for better surface quality or new specialty steels requiring high-quality surface features. All this lies on a table of new challenges faced by steelmaking industries, when energy efficiency and consequently lower environmental impact are concerned.

This international meeting aims to share knowledge about the improvement of the surface quality of the continuously cast products.

This scope will be achieved by clear expositions about:

- recent advances on defect analysis, including sensors and quality prediction systems;

- the root causes of defect formation;

- innovative solutions for continuous casting;

- operations and maintenance;

- AI applications, simulation and computing methods.

The workshop will be performed through invited presentation and on the basis of the selection of the abstracts sent by authors interested in sharing their updated knowledge in order to increase the surface quality of the continuous cast semis.

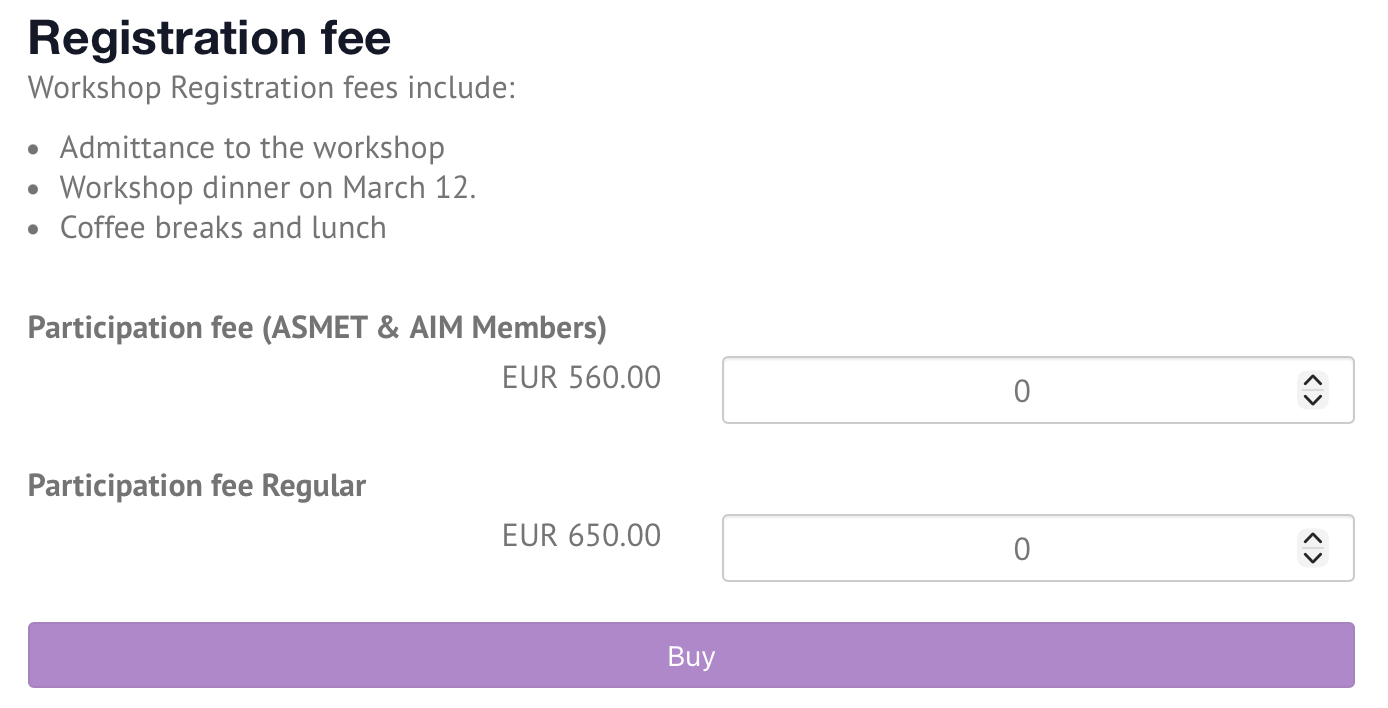

REGIATRATION

-

-

09:15

WELCOME COFFEE & REGISTRATION

-

Welcome AddressesConveners: Christian Bernhard (Montanuniversitaet Leoben), Riccardo Carli (Prosimet)

-

PANEL DISCUSSION: “MOLD FLUXES AT A CROSSROADS: PERFORMANCE, SUSTAINABILITY, AND FUTURE NEEDS”: Panelists: Jung-wok Cho - POSTECH, Marco Alloni - PROSIMET, Maité Cornille - ArcelorMittal R&D Maizieres, Matthias Rohmann - Calderys

Panel discussion:

Conveners: Nathalie Gruber (Montanuniversität Leoben), Riccardo Carli (Prosimet) -

12:00

LUNCH

-

IMPACT OF TUNDISH AND MOLD FLUXES ON PRODUCT QUALITYConvener: Jung-Wok Cho (POSTECH)

-

1

Approaches to carbon-reduced and carbon-free mold powders in the continuous casting of aluminum-alloyed steels

During the continuous casting of steels, a carbon-enriched layer forms on top of the liquid slag. Owing to fluctuations in the mold, liquid steel may come into contact with this layer, leading to re-carburization. Previous attempts to mitigate this phenomenon seemed insufficient for the intended applications; therefore, mold powders with reduced or zero carbon content are desired. For mold powders used in the casting of ultra-low-carbon (ULC) steels, the substitution of carbon with SiC, combined with a novel approach that separates components into two types of granules according to their basicity (“basic” and “acidic”), has already been demonstrated to provide suitable melting behavior. Based on these findings, this concept was extended to two mold fluxes designed for aluminum-alloyed steels. Both fluxes contain 2.2 wt.% Li₂O in the liquid state but differ in their chemical compositions: Flux MP 1 has a CaO/SiO₂ ratio of 0.61 and contains 6.8 wt.% MnO in the molten state, whereas flux MP 2 has a CaO/SiO₂ ratio of 1.17 and an Al₂O₃ content of 29.0 wt.%. In a first step, MP 1 was prepared from two types of granules, heated in a preheated furnace at selected temperatures between 900-1200°C for 10 minutes, quenched to room temperature, and subsequently analyzed mineralogically. However, due to the high content of volatile components, the results did not meet expectations. As a next step, CaC₂ was evaluated as a melt-controlling additive. In contrast to SiC, CaC₂ produced free carbon during heating, rendering its use unnecessary. Consequently, the suitability of SiC was also investigated for both mold powders, despite the relatively low SiO₂ content of MP 2. Both compositions exhibited melting behavior comparable to that of the respective standard mold flux, while in the case of ULC mold powders the samples containing SiC even outperformed the standard mold powder and SiC was still detected even at 1200°C. The beneficial behavior of SiC at temperatures above 1000°C could not be observed for MP 2, as it had already been consumed by reactions with other components. These results indicate that while the replacement of carbon by SiC is favorable for MP 1, this is not the case for MP 2. Subsequently, MP 2 was further investigated using the two-granule concept, in which basic and acidic components were prepared separately, mixed, and heated. In contrast to MP 1, this separation delayed the formation of new phases, particularly at lower temperatures, while resulting in a similar liquid phase fraction at elevated temperatures when compared to the standard flux. In summary, for mold powders used in the continuous casting of aluminum-alloyed steels, the necessity of SiC as a melt-controlling additive depends strongly on chemical composition. For fluxes with low CaO/SiO₂ ratios and significant MnO contents, the use of SiC remains beneficial. Conversely, for fluxes with high Al₂O₃ contents and associated high basicity, the two-granule approach allows the complete elimination of a melt-controlling additive from the mold powder.

Speaker: Nathalie Gruber (Montanuniversität Leoben) -

2

Design of mould fluxes for some challenging grades of steel - results from recent studies at IIT Kanpur

...

Speaker: Rahul Sarkar (IIT Kanpur) -

3

Alternative raw materials to control covering powders' sintering behavior

Tundish covering powders are prone to sintering, which leads to crust formation during steel

casting operations. Sintering occurs through atomic diusion within the microstructure, driven

by chemical potential gradients, and typically becomes significant at temperatures above

approximately 70% of the material’s melting point. To delay this phenomenon, carbon—

characterized by a very high melting temperature (≈3600 °C)—is commonly added to tundish

powders, forming a separating layer between components and postponing sintering until

carbon combustion occurs. However, for certain steel grades, carbon may act as a source of

recarburization, making its reduction necessary and prompting the search for suitable

alternatives. This study investigates the use of various high-melting-point components as

carbon substitutes in tundish covering powders, aiming to delay sintering and melting while

avoiding undesirable carbon pickup.Speaker: Milad Mahdi (Prosimet SpA) -

4

Development and application of a new tundish and low RCS powder

...

Speaker: Marc Faverjon (DEREF SpA)

-

1

-

15:10

COFFEE BREAK

-

FLUID FLOW IN SEN AND MOLD: SIMULATION AND MEASUREMENTSConvener: Carlo Mapelli (Politecno di Milano)

-

5

Continuous Casting Mold Flow with Original and Used Nozzle Geometries: Numerical Flow Simulations and Water Model Measurements

In continuous steel casting, the turbulent liquid steel flow in the mold has a significant influence on the produced steel quality. The varying process parameters casting speed and inert gas injection at the stopper rod tip influence the mold flow pattern. Most investigations consider the original geometry of the submerged entry nozzle. During the casting process, material deposition and erosion change the nozzle surface geometry continuously. The geometries of two used nozzles are determined by a 3D scan at voestalpine. Numerical multiphase flow simulations and 1:1 scaled water model experiments are performed for the used and unused nozzle geometries and compared. The used nozzle geometries show significantly different flow patterns in comparison to the original unused nozzle geometry.

Speaker: Mirko Javurek (Johannes Kepler Universität Linz, Institut für Strömungslehre und Wärmeübertragung) -

6

Ways to study fluid flow in the mould – The application of Simulation Technology and Supplementary Tools for SEN Design Characterization and its Development

Simulation-based analysis of flow phenomena in continuous casting moulds is a mature and well-established practice. Commonly applied approaches include Computational Fluid Dynamics (CFD) and physical modelling techniques, such as water modelling and, more recently, liquid metal experiments. These methods enable detailed evaluation of submerged entry nozzles (SEN) performance and support their optimization under varying process conditions. In addition, they play a critical role in the development of new refractory products. Final validation of simulation outcomes through in-situ measurements at the caster remains essential. This presentation reviews the simulation and experimental tools employed by RHI Magnesita and illustrates their application with selected case studies.

Speaker: Gernot Hackl (RHI Magnesita GmbH) -

7

State of the art on Measurement and Simulation of flow in the mould durch CC

...

Speaker: Pawel Ramirez Lopez (Swerim) -

8

to be announced

...

Speaker: Alma Olivos-Suarez (Tata Steel)

-

5

-

18:00

WORKSHOP DINNER - Location to be announced

Location to be announced

-

09:15

-

-

SURFACE QUALITY OF LONG AND FLAT SEMIS: PLANT RESULTS AND LAB EXPERIMENTSConvener: Thomas Griessacher (Stahl- und Walzwerk Marienhütte)

-

9

Effect of EMS Parameters on The Surface and Subsurface Defects

This work investigates the critical correlation between electromagnetic stirrer (EMS) operation in a continuous casting mold and the formation of internal defects in cast billets. While EMS intensity must be increased, particularly for square billet formats, to achieve sufficient molten steel agitation and homogenization, this study highlights the detrimental side effects of such intensification. The analysis focuses on the generation of strong azimuthal (rotational) flows, which can entrap inclusions and gas bubbles, leading to defect clustering. Furthermore, the intensified fluid dynamics significantly increase friction and shear stress at the billet solidifying corners, exacerbating corner crack formation and subsurface defects. The findings underscore the need for a finely tuned balance between stirring intensity and flow pattern control to optimize billet internal quality.

Speaker: Carlo Mapelli (Politecno di Milano) -

10

Influence of Mold Level Control Dynamics on Billet Surface Quality: A Quantitative Analysis

In the continuous casting of steel billets, the initial solidification at the meniscus is the critical determinant of surface quality. The shell characteristics and geometry are intrinsic features of the process, resulting from the interaction between mold process parameters and the solidifying meniscus. However, defects and irregularities significantly alter the local heat transfer coefficient in the mold and act as stress raisers, increasing the susceptibility to transverse cracking. This study investigates the direct correlation between the performance of different Mold Level control systems and the morphological characteristics of billet surface.

A comprehensive experimental campaign was conducted on a multi-strand billet caster. The trials involved the application of distinct mold level control strategies, characterized by varying response times and damping factors, to induce controlled variations in meniscus stability. The resulting oscillation profiles were analyzed to quantify their impact on the overall quality. To ensure robust data validation, the surface quality assessment employed a multi-technique approach. This involved the utilization of both conventional methodologies, such as direct visual observation and manual profilometry, and advanced techniques, including digital image recognition.

This study provides valuable insights for optimizing the casting process, identifying the most effective control strategies and measurement techniques to ensure consistent billet surface quality.

Keywords: Continuous Casting, Mold Level Control, Surface Quality, Digital Image Recognition.Speakers: Federica Di Giovanni (Feralpi Siderurgica S.p.A.), Giulia Buratti (Feralpi Siderurgica S.p.A.) -

11

Development of optimized continuous casting process for zero-defect round blooms production in high silicon 54SiCr6 automotive spring steel. Production trials in Acciaierie Bertoli Safau S.p.a

Surface quality is a well-known critical factor affecting the fatigue life of components. Therefore, the quality of the initial feedstock is mandatory for producing wire rod suitable for high stress applications, such as automotive suspension springs. This paper describes the successful experience of ABS (Acciaierie Bertoli Safau, Italy) during the development of a dedicated casting process of high silicon grade 54SiCr6 specifically intended for automotive applications. The development path is presented, highlighting the key improvements implemented. Crucial factors that allowed quality change are commented on (i.e. materials, process parameters, automated mould flux feeder, Non-Destructive controls). The step-by-step evolution of the learning process is fully described, showing the effects of each modification and the resulting improvements obtained to achieve a zero-defect cast product. Particular attention is paid to surface defects and to surface Carbon pickup phenomena. The satisfactory quality of the product achieved confirms the effectiveness of the optimization process.

KEYWORDS: SPRING STEEL, CONTINUOUS CASTING, MOULD POWDER, SURFACE QUALITYSpeaker: Sara Busolini (ABS - Acciaierie Bertoli Safau S.p.A.) -

12

Effect of Mn/S ratio on surface quality in continuous casting of steel

The required properties and the higher strength demands for steel products have been increasing in recent years, leading to the various production routes and the increase in the content of alloying elements. Furthermore, steel industries are facing pressure to transform their production processes to achieve a carbon-neutral society. In these environmental changes, maintaining and further improving the quality of casts produced by continuous casting are important issues. Since surface quality and defects of casts are known to be closely related to the high-temperature embrittlement of steel, a lot of research has been performed on this phenomenon.

This study focuses on high-temperature embrittlement caused by (Mn, Fe)S. Previous research using Gleeble indicated that the Fe content in (Mn, Fe)S and the size of (Mn, Fe)S precipitated along austenite grain boundaries are critical embrittlement factors [1]. In addition, the result showed that embrittlement did not occur under low strain rate conditions. In the present study, high-temperature embrittlement is evaluated using in-situ material characterization by bending (IMC-B) test [2-4]. The results show that embrittlement occurs even at low strain rate in medium-carbon steel with a low Mn/S ratio. This discrepancy seems to be because of differences between the evaluation methods of Gleeble and IMC-B test.

Furthermore, precipitation simulations of MnS are carried out using MatCalc, which enables kinetic precipitation calculations based on thermodynamic databases and kinetic models[5]. The simulation results are compared with observations by FE-SEM. This comparison provides interpretations of the embrittlement mechanism and strategies for the steel composition and process design to improve the surface quality of casts.References

[1] H. G. Suzuki: Tohoku University, Ph. D thesis, Tohoku University, (1981).

[2] R. Krobath and C. Bernhard: A New Experimental Setup for the Simulation of Surface Crack Formation in the Continuous Casting Process, AISTech 2017 - Nashville, United States(2017)

[3] R. Krobath and C. Bernhard: Experimental Quantification of Critical Parameters for Prediction of Surface Crack Formation in Continuous Casting, steel research international, 91(2020), 2000234. https://doi.org/https://doi.org/10.1002/srin.202000234

[4] G. Gaiser, R. Krobath, P. Presoly and C. Bernhard: The influence of intergranular oxidation on surface crack formation in continuous casting of steel, Journal of Materials Research and Technology, 26(2023), 9276. https://doi.org/https://doi.org/10.1016/j.jmrt.2023.09.214

[5] E. Kozeschnik: Encyclopedia of Materials: Metals and Alloys, ed. by F. G. Caballero, Elsevier, 978-0-12-819733-2, (2022), 521.Speaker: Takuya Takayama (Montanuniveristaet Leoben)

-

9

-

10:10

COFFEE BREAK

-

NEW ENGINEERING CONCEPTS FOR IMPROVEMENT OF SURFACE QUALITYConvener: Cosmo Di Cecca (Feralpi Siderurgica S.p.A.)

-

13

Mould design optimization for beam blank production

One of the typical quality problems of near-net-shape products such as the beam blank is the appearance of surface and sub-surface cracks. The complex shape of the mould makes the casting of crack sensitive grades particularly challenging. This paper describes the process of modifying an existing beam blank section to improve its quality performance. It starts with the analysis carried out to identify the root cause of the problem, then explains the design principles and finally presents the industrial results obtained with the new design and its optimization.

Speaker: Mr Stefano Baf -

14

Our Segments like it hot – how Smart Segment Engineering directly influences Slab Surface Quality

Continuous casting of slabs demands stringent control of thermal and mechanical conditions to ensure crack-free surfaces and dimensional accuracy. The rising concentration of tramp elements in steel, resulting from modern steelmaking practices, significantly increases susceptibility to hot cracking, particularly within the straightening zone. Maintaining temperatures above the second ductility trough is therefore critical. Smart Segment Engineering addresses these challenges through advanced design concepts such as Eco Star spiral rolls, enabling dry casting and eliminating secondary cooling infrastructure, thereby simplifying segment architecture. High structural stiffness minimizes bulging and mechanical deformation, while precise segment alignment—supported by tools like the Strand Checker—ensures consistent slab geometry as well as excellent internal quality. These integrated solutions deliver homogeneous temperature profiles and superior surface quality, establishing Smart Segment Engineering as a key enabler for reliable, high-performance continuous casting operations.

Speaker: Dr Kerstin Baumgartner (Primetals Technologies Austria GmbH)

-

13

-

11:30

LUNCH

-

SURFACE QUALITY PREDICTION IN CC AT THE CROSSROADS: FROM PHENOMENOLOGICAL MODELS TO DATA DRIVEN MODELS AND HYBRID APPROACHESConvener: Christian Bernhard (Montanuniversität Leoben)

-

15

AI powered surface inspection for billets - next generation quality control

Rising demands on the surface quality and the necessity for 100% inspected billets are requested by the customers. Surface defects on billets, like longitudinal or transversal cracks, can – if not removed e.g. by grinding - lead to increased reject rates, or in the worst case to a complete production stop, in the further rolling process route.

The surface inspection at voestalpine Stahl Donawitz was based on an image classification algorithm which was trained to detect specific defects on the billets. Although most of the surface defects could be detected and classified, this algorithm showed a high false positive rate, so the operators at the rolling mill had to check each detected pseudo defect, which was a time consuming and error prone procedure. The new project aims to replace the old image classification algorithm with a new AI-based object detection model by using the same camera setup. This AI based supervised deep learning model uses the technique of a sliding window and a convolutional neuronal network, more specific a residual network (ResNet34), to increase both the accuracy and the precision of the predictions of each image patch. In addition, a customized graphical user interface (GUI) was developed to increase workers' confidence in the new system, significantly reducing the need for manual follow-up checks. To improve the detection accuracy as well as the precision the standard camera was replaced with a multi spectral camera. This opens up new perspectives by using the blue spectrum of the light which leads to an increased depth perception and a steep increase in the detection rate.Speaker: Gerald Klösch (voestalpine Stahl Donawitz) -

16

Utilization of Artificial Neural Networks for Prediction of the Slab Surface Crack Formation

Designing the continuous casting process of advanced high strength steels(AHSS) requires precise simulation of fracture formation based on high-temperature properties of steel grades and casting conditions in order to minimize surface defects of the slab. Reduction of area(RA) as an indicator of ductility was utilized to correlate with the cracking performance of the continuous caster of Pohang Steel Works. The RA curve of each steel grade was predicted using a Gaussian fitting-based ANN model that learned accumulated measurement data of over 3,000 data points from high temperature tensile tests. Uneven solid-shell index(USI) as another indicator of crack sensitivity of a steel grade was also introduced by thermal analysis using differential scanning calorimetry(DSC) and by calculating volumetric shrinkage of the slab surface during initial solidification based on the thermodynamic database of JMatPro. Each type of surface crack seemed to be influenced by different mechanisms, where longitudinal face cracks increased with USI while transverse cracks showed a relatively high correlation with predicted RA. However, it was difficult to assure that either USI or RA independently determined the frequency of a certain type of cracking with absolute Pearson’s correlation values of less than 0.6. Classification of cast slabs based on USI and RA indicated that the combined effect of initial solidification and ductility behavior in the strand bow determines crack frequency for diverse types of cracking such as corner cracks, transverse cracks, and longitudinal face cracks. The ANN-based surface crack prediction model in which simulated RA and USI were introduced as derived variables resulted in higher precision of 0.84 compared to the model with a precision of 0.80 only including steel composition and casting parameters excluding the simulated physical propreties.

Speaker: Sung-Suk Jung (Posco) -

17

Phenomenological prediction of surface defects: Fundamentals, tools, and results from slab casting

The surface quality of continuously-cast products remains an important research topic due to its economic and practical implications for steelmakers. Surface quality problems are generally attributed to the presence of various kinds of defects originating from continuous casting. While the root causes of defects can be considered well-defined in scientific literature today, a frequent shortcoming in quality prediction is that the defect formation mechanisms have not been incorporated into the models. The common approach is to utilize caster data and machine learning algorithms with defect information as labels in classification. These approaches are often data-driven with limited interpretability and metallurgical assessment. To construct a phenomenological approach, machine learning models need inputs that describe the various metallurgical phenomena related to defect formation. This invited presentation provides an overview of the phenomenological approach developed for the prediction of surface defects in slab casting. The fundamentals of defect formation are briefly addressed, after which the InterDendritic Solidification (IDS) and CastManager tools utilized in the online simulation of solidification, microstructure evolution, and heat transfer are presented. Finally, progress and recent results from industry-academia collaboration in Finland are highlighted regarding the phenomenological prediction of longitudinal cracks, transverse cracks, and slag defects.

Speaker: Julius Norrena (University of Oulu) -

18

AI-Enhanced Mold Monitoring

The quality of continuously cast slabs is strongly influenced by steel grade and casting parameters. The Strand Quality Index (SQI) enables probabilistic prediction of crack formation based on these factors. By integrating the Mold Expert, which calculates depressions in the mold using temperature profiles, the SQI now receives additional event information, significantly improving the accuracy of quality issue forecasts.

Furthermore, we present an innovative approach to determining the meniscus profile using AI-based models trained on temperature data from horizontal optical fibers. This technology drastically reduces investment costs compared to vertical optical fibers, offering a cost-efficient solution for process monitoring.

Combining these methods results in enhanced prediction accuracy and more economical monitoring of the continuous casting process.

Speaker: Oliver Lang (Primetals Technologies Austria) -

19

Process Chain Sensitivities in Green Steel Production: Tramp Element Impacts on Casting, Reheating and Descaling

The transition toward low-carbon steelmaking increases the reliance on scrap-based electric arc furnace routes, inevitably introducing higher levels of tramp elements such as Cu and Sn. Because these elements cannot be removed through conventional metallurgical refining, they may influence subsequent process steps. Their distinct oxidation behavior promotes the formation of low-melting, Cu-rich phases during continuous casting and reheating. Even at moderate concentrations, these phases significantly intensify crack formation during casting, increasing both the number and depth of surface defects across a broad temperature range compared to steels free of Cu and Sn. Such defects pose a particular risk in downstream operations, where they can persist depending on reheating conditions. Deep casting-related defects may not be fully removed under standard parameter sets, which in turn hampers descaling efficiency. During reheating, the prolonged exposure promotes the formation of additional Cu-rich phases, which can further degrade surface integrity. As a result, remaining surface irregularities, together with grain boundaries already weakened by Cu phases, can compromise the quality of the final hot-rolled product.

The presentation quantifies the defect sensitivity of Cu- and Sn-containing steels using the in-situ material characterization by bending (IMC-B) test. Purposefully pre-damaged samples were produced to simulate how those defects may affect downstream processing. These specimens were subsequently reheated in a natural-gas combustion atmosphere and descaled under controlled conditions to evaluate the evolution and removability of surface defects. Final surface assessments were conducted using metallographic techniques, enabling correlation between Cu and Sn, defect morphology, reheating behavior, and descaling response.Speaker: Georg Gaiser (Montanuniveristaet Leoben)

-

15

-

15:05

Concluding remarks, closure of workshop: Riccardo Carli and Christian Bernhard

-